CMP Equipment

Polisher Standard Features

Built-in high-pressure water jet pad cleaner

Pad diamond dresser and pad brush cleaner

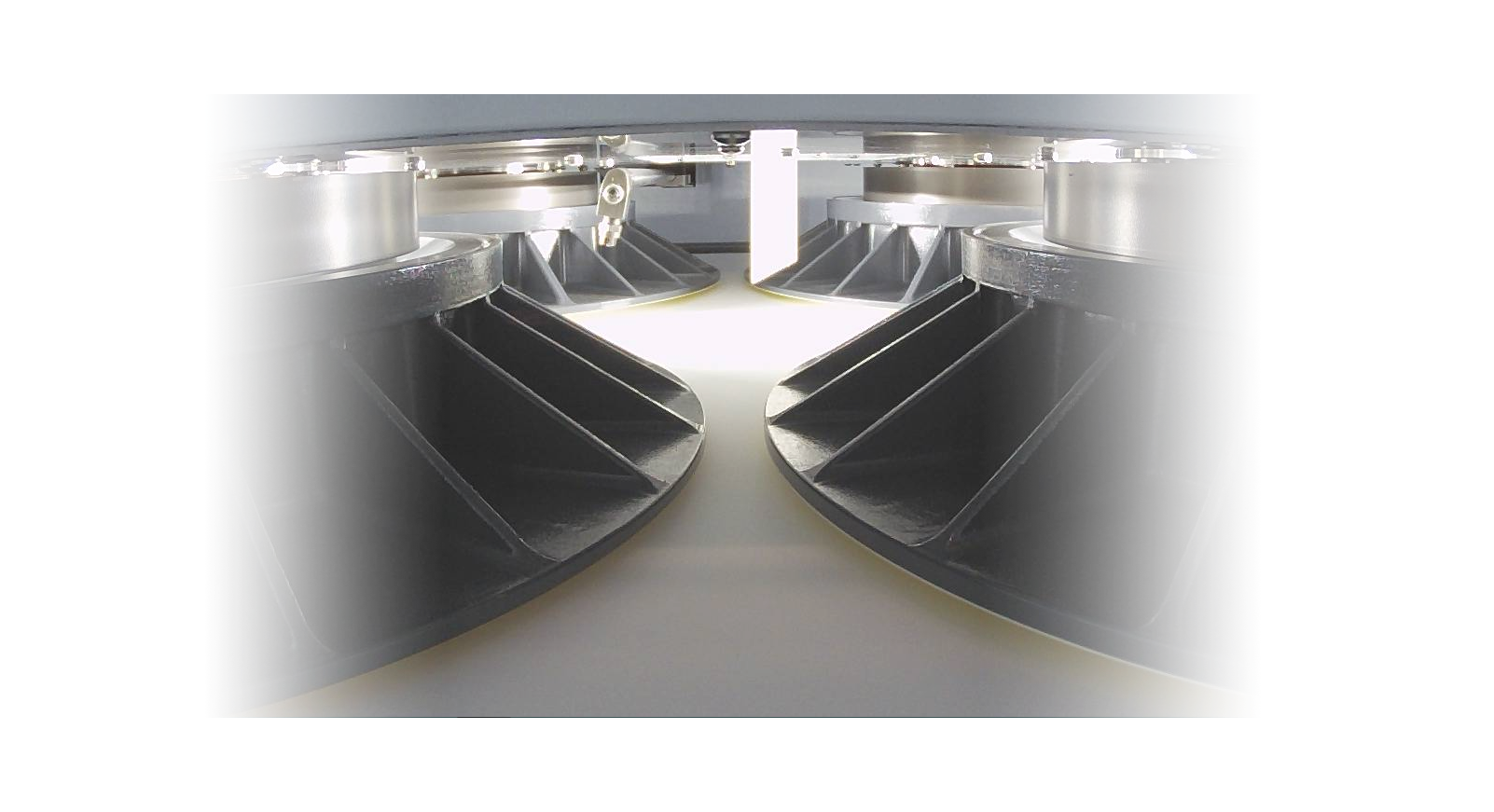

Batch wafer processing: High-productivity batch processing CMP systems

Single wafer processing: Single wafer, four (4) spindle CMP equipment

Model 3806

150mm silicon wafer polisher with template process

Up to 6" wafer polishing capabilities, including silicon, quartz, LiNi, Sapphire, Silicon carbide, Germanium ….

Lowest Cost of Ownership with high production throughput and low maintenance requirements

State-of-the-art touch screen recipe control PC

Three-way valve slurry recovery

Wax mount conversion kit

Network capabilities SECS/GEM

Turn key solution available

Single Wafer Polishing

GigaMat Technologies also offers any of its polisher models as single wafer per head variants as well. The single wafer per head polishing variants can polish any wafer size up to 300mm.

Model 3808

200mm silicon wafer polisher with template process

Up to 8 " wafer polishing capabilities, including silicon, quartz, LiNi, Sapphire, Silicon carbide, Germanium….

Lowest Cost of Ownership with high production throughput and low maintenance requirements

State-of-the-art touch screen recipe control PC

Three-way valve slurry recovery

Wax mount conversion kit

Network capabilities SECS/GEM

Turn key solution available

Model DM-18

GigaMat Technologies Demount station is used to remove wafers safely from the GigaMat polisher carrier plate after polishing. The Demount station uses fresh DI water from the supply line to protect wafers from any damage and provides a safe means of transfer into cassettes.

Benefits:

Increases yields by eliminating wafer scratches.

Prevents staining by storing the wafers under DI water immediately after demount.

Sensing of wafer coming into the cassette and carrier presence helps to save DI water usage.

Model 3808-LMD

Max 300mm silicon wafer polisher (Patented)

Implementing head oscillation feature needed to polish one wafer per polishing carrier.

Achieve processing of one to four 300mm wafer per polishing run.

Oscillation movement originates with the drive box and travel distance is five (5) inches.

Up to 12" wafer polishing capabilities, including silicon, quartz, LiNi, Sapphire, Silicon carbide...

Implementing Head oscillation feature

Template or Wax mount

Turn key solution available

Mounting Station

The Mounting Station was designed to mount semiconductor wafers onto semiconductor wafer carriers. The plate that is being pushed down onto the semiconductor wafer carrier is cushioned. To ensure safe operation, the machine is also equipped with a light curtain that will shut off power to the machine should the operator trip it.